News & Trends

Forging ahead with the circular economy

Think in the round!

Our knowledge of the finite nature of our resources is shaking the foundations of the „old order“: after losing votes in the latest European election, even the established parties are starting to focus on climate protection. This includes the circular economy where a host of companies are coming up with extremely innovative ideas.

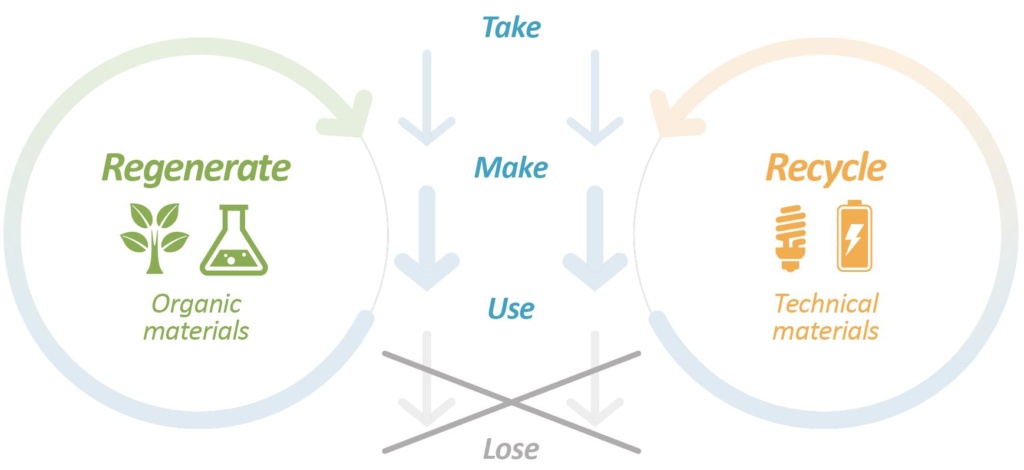

Circular economy at a glance: Regenerate and return instead of losing

But how can you tell what is merely a marketing ploy from a truly closed-loop materials cycle?

Treat yourself to a Fair Trade coffee after sorting through your rubbish. Of course the coffee powder doesn’t go to waste, it’s put straight onto flowerbeds as a form of plant fertilizer. If only everything would

soothe the ecologist’s ego as effectively as recycling. And actually there are other breakthroughs: fancy trying out the first „cradle-to-cradle“ (C2C) certified perfume – PuraVita?

THE STARTING POINT IS THE NEW ENDPOINT

The C2C principle has been devised by the US architect William McDonough and the German chemist Michael Braungart as an antidote to the linear „buy, use and discard“ way of doing things. The idea is to

develop products from the outset so that there isn’t a single component which ends up as unusable waste – instead everything forms part of a continuous loop – a biological loop in the case of a toxic-free, fully compostable T-shirt made by the Trigema company, or a technological loop in the case of the office chair made by Steelcase where all the individual components can be reused.

The circular economy is inspiring both small and large companies, and established ones as well as new ones. According to a 2016 report by the Xinhua News Agency, 26 million tonnes of textile waste is discarded as rubbish in China every year. But there’s a concerted backlash against „fast fashion“. For example, the „YCloset“ company is offering an online fashion subscription service: it provides an inexpensive way for China’s growing middle classes to try out numerous styles and then to hand them back after using them. The high usage rate reduces waste, and it saves resources and the environment.

And have you heard? About 15 million tonnes of headphones end up being thrown away every year. Now you can subscribe to the hipster headphones produced by Gerrard Street. The British start-up produces them as a modular system. So they can be customised, upgraded, or quickly repaired.

„In Apple’s „Material Recovery Lab“ engineers undertake joint research with universities.“

THE ‚WASTE APPLE‘ IS CHANGING EVERYTHING

Apple is reinventing itself again. In its latest environmental report the company comes up with some interesting facts and figures. Thanks to „Daisy“, a robot which dismantles 200 used iPhones in an hour, 48,000 tonnes of electronic waste can be recycled.

There’s good news in relation to aluminium too: the housing of the new Mac Mini and Macbook Air is made of 100 percent recycled aluminium – halving its CO2 values compared with the predecessor models. The fact that the circular economy is more than just short-lived hype is also shown by Apple’s recently opened „Material Recovery Lab“. Here engineers undertake joint research with universities in the search for new ways to implement the circular economy.

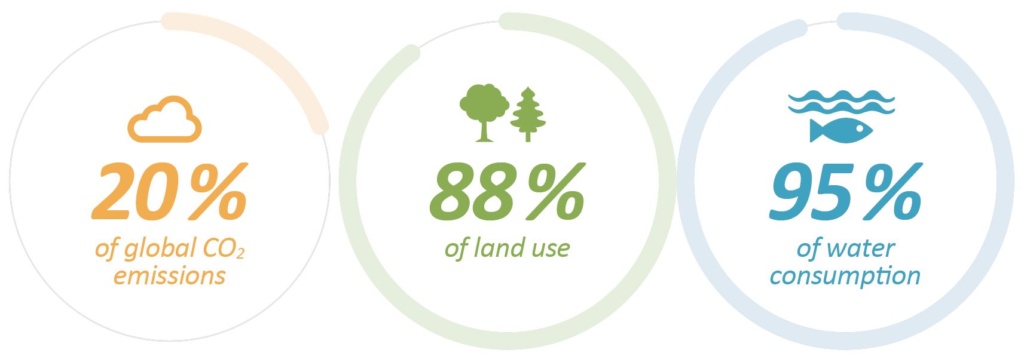

8 materials* are responsible for:

Quelle: Circular Economy, Ecoflys & WBCSD

THERE’LL SOON BE MORE RUBBISH THAN FISH.

In a cartoon a woman asks a shop assistant for a plastic bag for her fish. He replies: „The plastic bag’s already in the fish.“ It’s no joke: by 2050 there could be more plastic by weight than fish swimming around in our oceans.

Every recycled plastic bottle is better than the alternative: 20 percent less air pollution and 50 percent less water pollution is the outcome compared to a conventional bottle. The New Plastics Economy is also

well aware of this. Its 290 members ranging from the producers of packaging to food suppliers produce 20 percent of the world’s plastic packaging.

They’ve agreed on three key points:

1. “Eliminate”

When there’s no need for plastic, simply leave it out.

2. “Innovate”

By 2025 the aim is that all plastic packaging should be compostable or able to be recycled

in other ways.

3. “Circulate”

Produced plastic shouldn’t end up as landfill or in the oceans, it should be part of a circular economy.

The European Commission forecasts that by 2030 the circular economy could produce savings of 600 bn. euros as well as creating two million new jobs. Hardly a picture of economic nonsense and dour self-denial. So let’s think in the round.

GLOBALANCE FOOTPRINT

The circular economy becomes a competitive advantage.

Thinking in terms of closed-loop cycles involves more than technological engineering skills:

80 percent of waste is generated in our heads. For instance, if the design doesn’t take into account the question of whether the materials can simply be separated and reused later on.

But people are starting to think about the issues in different ways: technological innovations together with new business models are revolutionising the linear (wasteful) economy. Although the established idea of recycling is a principle of the circular economy, it’s not fully living up to people’s expectations of it, and so fi rms are reinventing their business.

Products are being hired out rather than sold. Collecting and taking back is the idea – generating new sources of income that didn’t exist in the old throw-away society.

GLOBALANCE FUTUREMOVER

Successful companies see challenges as an opportunity for innovation.

The rest is pure economics: if you use fewer resources you earn more.

Eliminate: Unilever N.V., the world’s fourth-bigges producer of consumer goods, wants to halve the environmental impact of the goods that it produces by 2030. The company is on course to achieve this: the weight of plastic packaging that it uses has already been cut by almost a third. This makes a big impact when you consider its EUR 50 bn. annual turnover.

Innovate: BioMason – A US-based private start-up is revolutionising the construction industry: by inventing the climate-friendly brick. These are not fired in a furnace, instead they are created from sand through the of bacteria – without any CO2 emissions. The energy-saving potential is huge: a whopping 800 million tonnes of CO2 are generated every year through the worldwide production of bricks.

Circulate: Black Bear Carbon – A billion car tyres are disposed of every year and diverted from the circular

economy. The Dutch company, Bear Carbon, is a technological pioneer in the upcycling of used tyres. If all the available used tyres were recycled every year annual global oil consumption would be reduced by 215 million barrels.